|

Contents

1. Business Process Management: a Big

Picture

Balanced Business System

Corporate Growth Strategies

Business Process: Definition and

Characteristics

Extended Enterprise

Business Process Outsourcing (BPO)

2. Enterprise-wide Business Process

Management (EBPM)

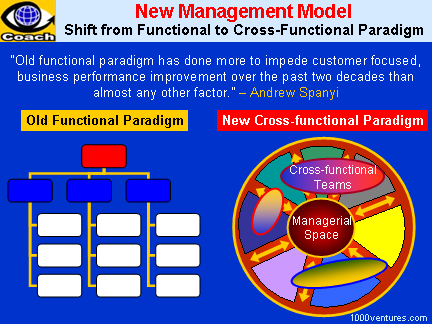

Shift from Functional to

Cross-Functional Paradigm

The Payoffs of Process Approach to

Business

Process Thinking

EBPM Assessment Form

8 Essential Principles of EBPM

Cross-functional Management (CFM)

E-Business – Benefits and Opportunities

Customer Relationship Management (CRM)

Aligning Information Technology (IT)

and Business

Business Process Management System

(BPMS)

11 Traits of an IT Architect and a True

IT Leader

3. Continuous Improvement, Kaizen, Lean Production

Continuous Improvement Firm (CIF)

Japanese

Suggestion System: Goals and Benefits

Japanese-style Individual-based

Suggestion System

STRIDES: a Model for Solving Complex

Problems

Kaizen – Japanese Strategy for

Continuous Improvement

Kaizen Mindset

Kaizen: 7

Conditions for Successful Implementation

Quick and Easy Kaizen

Best Practices:

Practicing Kaizen at Fidelity Investments

Best Practices:

Employee Empowerment at Fidelity Investments

Kaizen and Radical Innovation

Lean Production – Doing More With Less

Lean Production: 7 Wastes To Be

Eliminated

Typical Benefits of Lean Production

An Overview of Lean Production

Components of Lean Production System

Just-In-Time (JIT) Manufacturing

Best

Practices: Toyota Production System (TPS)

Best

Practices: 7 Principles of Toyota Production System

(TPS)

Best

Practices: Canon Production System (CPS)

Best

Practices: Canon Production System (CPS) – Key

Structures

Case Study:

Lean Manufacturing at GSEP Ltd. (India)

Case Study:

Lean Manufacturing at Automotive Companies (USA)

10 Commandments of Lean Production and

Improvement

4.

Quality Management, Six Sigma

Computing the Cost of Quality

Total Quality Management (TQM)

Deming's 14 Point Plan for TQM

Kaizen and TQM

Areas Targeted by TQM in Japan

Japanese TQM Model

Best

Practices: 14 Slogans for TQM at Pentel. Japan

Lessons

from Jack Welch:

Live Quality

8 Rules for Managing Quality

Six Sigma: Benefits of Reaching Higher

Sigma Levels

Case Study:

Impact of Six Sigma Implementation at GE

Case Study:

Making the Six Sigma Process Work at GE

Integrating Six Sigma With Business

Process Management

Integrated Environmental and Quality

Management System (EQMS)

5. Process Innovation, Innovation

Process

Managing Operations vs. Managing

Innovation

The Tao of Business Process Innovation

Best

Practices:

Process Improvement at Fidelity

Investments

Innovation Process: Traditional and

Flexible Model

Case Study:

Attributes of Effective Innovation in Silicon Valley

The Jazz of Innovation

|

Transforming the

Traditional Functional Mindset

Excerpts from

BPM

- Approaches & Best Practices

by Andrew Spanyi

In far too many organizations, senior

management's traditional functional mindset represents one of the

most significant barriers to change. Indeed, there is reason to

believe that the traditional

functional paradigm has done more to impede customer focused,

business performance improvement over the past two decades than

almost any other factor.

This way of thinking stands in the way

of executives understanding and improving the flow of

cross-functional activities which create enduring value for

customers and shareholders. It promotes the type of thinking that

impedes the effective deployment of enabling information technology.

It promotes also 'silo behavior' and turf protection, and an undue

pre-occupation with organization structure. This mindset contributes

to the mistaken belief that if it was somehow possible to properly

define the boxes on the organizational chart, and fill in the names

of the "right" people in the key boxes - then the organization's

performance will automatically improve. Yet, little is further from

the truth. Further, it encourages a distorted view of performance

measurement and executive rewards, shifting focus away from

meaningful measures such as the timeliness and quality of services

provided to customers, and towards less significant measures around

functional departmental performance.

It reinforces a task focus and

traditional command and control behavior, where questions such as

'What is the scope of my responsibility?' and 'Who are the key

subordinates who can help me look good?' are foremost and top of

mind. Moreover, traditional functional thinking has also led to

outdated management practices in the areas of goal setting and

problem solving and it stifles innovation. So what to do? How can

you transform the traditional functional mindset such that your

organization is designed to make it easy for customers to do

business with the company and easier for employees to better serve

the company's customers?

An effective way of transforming the

traditional functional mindset is to embrace enterprise business

process thinking and install enterprise business process management

(EBPM) practices. What does this involve? Frankly, it requires a lot

of very hard work, and concepts which will make some of your

executives very, very uncomfortable. Why do it? Simply because the

benefits of making this mental model transition are significant.

|