| |

Kaizen & TQM

is a movement aimed at

continuous improvement of

managerial performance and

quality at all levels.

Kaizen calls for relentless

efforts for improvement

involving everyone in the

organization.

TQM is a management tool

for improving total performance.

|

|

|

|

|

|

|

Successful Company

In

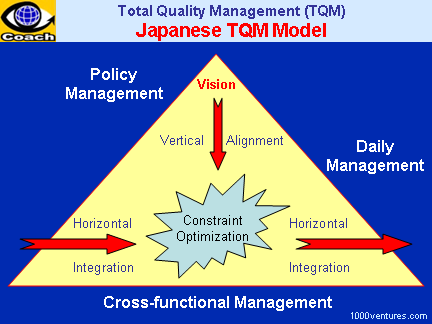

Japan, TQC activities are

not limited to quality control

only. Elaborate system of Kaizen

strategies has been developed as

management tools within the TQC

approach. TQC in Kaizen is a

movement aimed at improvement of

managerial performance at all

levels as well as

cross-functionally.

|

|

|

|

Education and Training

As

a natural follow-up to the

concept of building quality into

people, TQC starts with

education and training of

managers and workers. The major

aim of these awareness and

training programs is to implant

TQC thinking in all employees.

|

|

|

|

|

7

Main Features of the TQC Movement in

Japan |

-

Company-wide TQC, involving all employees, organization,

hardware, and software

-

Emphasis on

education and training

for

→

top management, middle management and workers

-

Quality control

(QC) circle activities by small

groups of volunteers

-

TQC audits

-

Application of statistical methods

-

Constant revision and upgrading of standards

-

Nation-wide TQC promotion

|

|

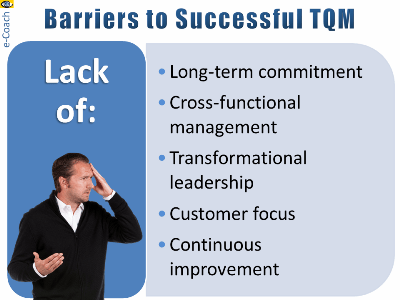

TQM Requires

Cultural

Transformation

With TQM quality is not the product but the

process. To institute the process, corporate trainers must bring about a

→

cultural transformation wherein all employees shed their individualism

for a unified set of

corporate

values.

TQM was the brainchild

of

Dr. W. Edwards Deming. TQM helped Japan with its postwar economic

recovery. That was because it meshed with

Japanese

→

culture. The Japanese

sense of responsibility to one's superiors and subordinates made it easier

to accept Deming's message that management's role was to provide the optimal

conditions for the workers to do the best job. The Japanese then extended

Deming's teaching to many dimensions of management.

The Three TQM

Goals at Japan Steel Works The Three TQM

Goals at Japan Steel Works

-

To provide products and

services that

satisfy customer requirements and earn customer trust

-

To steer the corporation

toward higher profitability through such measures as improved work

procedures, fewer defects, lower costs, lower debt service, and more

advantageous order filling

-

To help employees fulfill their potential

for achieving the

→

corporate goal, with particular emphasis on such

areas as policy deployment and voluntary activities

|

|

References:

-

"Productivity Improvement in the Service Sector," Mah Lok Abdullah, APO

Newsletter

-

Kaizen:

The Key To Japan's Competitive Success, Masaaki Imai

-

Gemba

Kaizen: A Commonsense, Low-Cost Approach to Management, Masaaki Imai

|

|

|

|