| |

Toyota’s global

sustainable competitive advantage

is based on a corporate

philosophy, an integrated socio-technical management system and

practices

known as the Toyota Production

System (TPS). |

|

|

| |

|

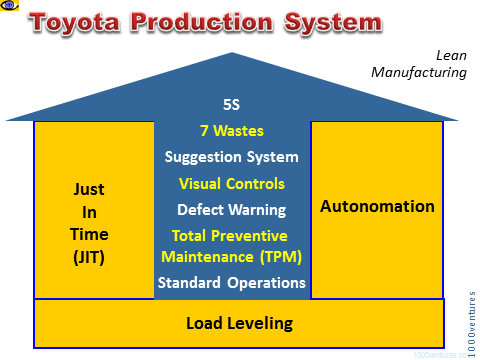

The Focus of TPS

Toyota Production System (TPS)

is

not just about “5Ss”

or “pull production” or “flow”” or "load leveling". |

|

|

| |

Specific Factors Underlying Toyota's Success

An effective and efficient human resources management system, the

cornerstone of which is a high level of employee loyalty and

commitment to quality

A state-of-the-art assembly system incorporating the latest robotic

technology

A well-coordinated network of world-class suppliers

A highly effective and efficient

just-in-time (JIT) inventory system |

|

Toyota Corporate Culture

5Ss

Continuous Improvement Mindset

Japanese Suggestion System |

|

|

|

|

Toyota

Suggestion System: Typical Annual Results

More than 700,000 improvement

suggestions

were submitted by Toyota's employees.

That is an average of over 10

improvement suggestions per employee per year.

Over 99% of suggestions were

implemented. |

|

|

|