|

|

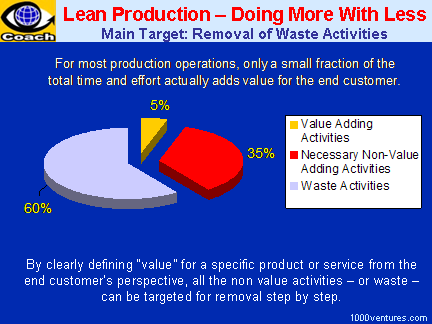

Lean is about doing more with

less: less time, inventory, space, labor, and money.

Lean manufacturing is about commitment to eliminating waste, simplifying procedures and

speeding up production.

The idea is to pull inventory through based on

customer demand. |

|

| |

Lean Manufacturing also

known as the Toyota Production

System (TPS)

is, in its most basic form,

the systematic elimination of

waste overproduction,

waiting, transportation,

inventory, motion,

over-processing, defective units

and the implementation of the

concepts of continuous flow and

customer pull. By continually

focusing on waste reduction,

lean enterprises can achieve

unlimited benefits.

Five areas drive lean

manufacturing: cost, quality,

delivery, safety, and morale.

Value is defined by the

ultimate

customers needs.

|

|

Continuous

Improvement Firm (CIF)

Kaizen and Lean Manufacturing

Kaikaku-Kaizen Journey

Implementation

Suggestion

System

Examples

of CIF |

|

|

|

|

Key Features of Lean

Production

compared

to Traditional Mass Production |

-

Reduced Setup Cost and

Times (for semi-versatile

machinery such as big stamping presses)

from months to hours thus making

small-lot production economically viable; achieved by organizing

procedures, using carts, and training workers to do their own setups,..

More

|

|

Strategy of Lean Production |

|

|

|

Benefits of Lean Production

Establishment and mastering of a

lean production system would allow you to achieve the following benefits:

-

Waste

reduction by 80%

-

Production cost reduction by 50%

-

Higher

→

quality

-

Manufacturing cycle times decreased by 50%

-

Labor reduction by 50% while maintaining or

increasing throughput

-

Inventory reduction by 80% while increasing

customer service levels

-

Capacity in current facilities increase by

50%

-

Higher

→

profits

-

Higher system flexibility in reacting to

changes in requirements improved

-

More strategic focus

-

Improved cash flow through increasing

shipping and billing frequencies

However, by continually focusing

on waste reduction, there are truly no end to the benefits that can be

achieved.

→

Kaizen: 5 Principles

→

Kaizen Culture:

8 Key Elements

→

Implementing Kaizen:

7 Conditions

Characteristics

of Lean Manufacturing Systems

-

Close integration of the whole

→

value chain from raw material to finished product through partnership

oriented relations with suppliers and distributors.

-

→

Team based work

organizations with multi skilled operators empowered to make decisions

and improve operations with few indirect staff...

More

Toyota Toyota

Three Small- and Medium-Sized Firms, U.S.A. Three Small- and Medium-Sized Firms, U.S.A.

Smaller and

mid-sized organizations pride themselves on being nimble quick to respond

and to

seize

opportunities. Many believe smaller size is more manageable; and that

internal communications in a

smaller group

can be maintained so employees can take ownership of more than their own

corner of the enterprise. One key to success is maximizing resources and

discovering inventive ways to overcome budget limitations. Another trend is

moving from a PUSH system

building to

forecasts

to a PULL system, building in response to

orders...

More

|

|

References:

-

Relentless Growth, Christopher Meyer

-

"Competitive Manufacturing Management", John M. Nicholas

-

"The Lean Journey" White Paper by Oracle Corporation

-

"TPS vs. Lean and the Law of Unintended

Consequences," Art Smalley

-

"Lean Thinking," James Womack and Daniel Jones

-

Lean Manufacturing That Works, Bill Carreira

-

The

Toyota Way, Jeffrey Liker

-

Toyota

Production System,, Taiichi Ohno

-

"Kanban

Just-In-Time at Toyota," Japan Management Association

-

"Lean

Production Simplified," Pascal Dennis, John Shook

-

"The

Lean Manufacturing Pocket Handbook," Kenneth W. Dailey

-

"Lean

Six Sigma," Michael

L. George

-

Kaikaku: The Power and Magic of Lean, Norman Bodek

|

|

|

|