| |

|

Continuous Improvement Firm (CIF)

Kaizen

and

Management

|

|

|

|

|

If you implement a radical improvement (Kaikaku), you must follow it with Kaizen.

Radically-improved objects tend to return to their original state if a radical improvement (Kaikaku) is not followed with small continuous improvements (Kaizen)...

More |

|

|

The

competitor to be feared is one who

never bothers about you at all, but

goes on making his own business

better all the time. |

Henry Ford |

| |

"Kaizen

means ongoing improvement

involving everybody, without

spending much money... You can't

do Kaizen just once or twice

and expect immediate results.

You have to

be in it for the long haul."

~

Masaaki Imai

|

|

|

| |

Kaizen and Management

Management has two major

components:

①

maintenance, and

②

improvement.

The objective of the maintenance

function is to maintain current

technological, managerial, and

operating standards. The

improvement function is aimed at

improving current standards.

|

|

|

| |

Under the maintenance function,

the management must first

establish policies, rules,

directives and standard

operating procedures (SOPs) and

then work towards ensuring that

everybody follows SOP. The

latter is achieved through a

combination of discipline and

human resource development

measures.

Under the improvement function,

management works continuously

towards revising the current

standards, once they have been

mastered, and establishing

higher ones.

|

|

Kaizen

Kaizen

Mindset

7

Conditions

Quick and

Easy Kaizen

Kaizen and TQM

Kaizen Culture

8 Components |

|

|

| |

Improvement can be broken down

between

innovation and Kaizen.

Innovation

involves a drastic change in the

existing process and requires

large investments and big

efforts.

Kaizen

signifies small improvements as

a result of coordinated

continuous efforts by all

employees.

|

|

|

| |

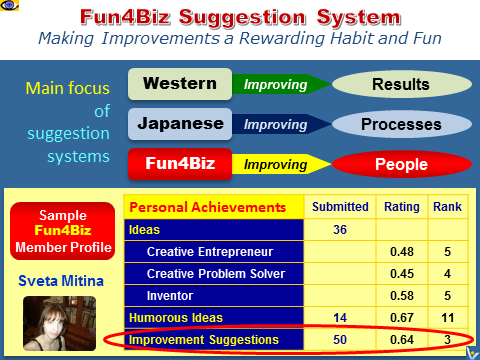

Fun4Biz is a vertical social

network – it helps people grow

as creative entrepreneurs.

The primary goal of the Fun4Biz

suggestion system is to

improve people, to unlock their

creative power and make

continuous improvement an

enjoyable habit...

More

|

|

|

|

|

|