| |

|

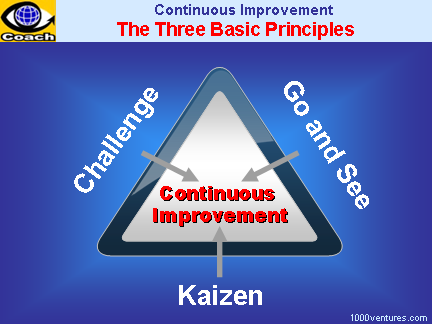

3 Basic Principles of Continuous

Improvement

①

Challenge

②

Kaizen

③

Go and See

|

|

|

|

Mediocrity competes with

others.

Greatness

competes with itself.

~

Vadim

Kotelnikov |

|

If you stop

learning, you stop

creating history and become

history.

If you are not

getting better, you are

getting worse.

Strive to be better than what

you were yesterday, not

someone else.

|

|

| |

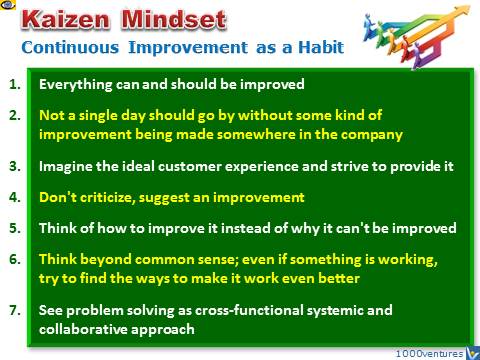

②

Kaizen

Establishing the

Kaizen Mindset is the starting point of the

continuous improvement journey. Everything can

and should be improved. |

|

|

|

Continuous improvement mindset is a

deep-seated, often

unconscious, desire or inner need that drives relentless search for

improvement opportunities and related actions. Everything can and should be

improved ‒ look for improvement opportunities constantly and pursue them

proactively. |

Vadim

Kotelnikov

Vadim

Kotelnikov |

|

Inventor

Author

Founder |

| |

③

Go and See

(Genchi Genbutsu)

This is a key

principle of the Toyota Production System (TPS).

The only way to truly understand what happens on

the shop floor ( 'gemba') is to go there. It is

here that value is added and here that waste

could be observed. 'Go and See' is therefore a

key approach in

problem solving. |

|

|

| |

If the

problem exists on the shopfloor then it

needs to be understood and

solved at the shop floor. Since real value

is created at the shop floor in manufacturing,

this is where management need to spend their

time. Go to the source to see the facts for

oneself and make the right decisions, create

consensus, and make sure goals are attained at

the best possible speed. This attitude of "Go

and See" is also called Gemba attitude. |

|

Problem

Solving

6 Steps

4 Levels

Work Backwards

5-Why Process

Creative

PS |

|

| |

|

Making the Kaizen Mindset Work

|

|

|

| |

2. Teamwork:

Develop individuals through teams-based

problem-solving. Engage people and develop them

through their contribution to team performance.

The are three team levels: shop floor teams, the

whole site as team, and the whole company as a

team. |

|

|

|

The main purpose of production

is to improve the life for

everyone and it is this goal

that I am dedicated. |

Konosuke

Matsushita |

|

After

materials are carried into the factory,

nothing but products should be carried

out from it.

|

Soichiro

Honda |

|

Whenever I go on a ride, I'm always thinking

of what's wrong with the thing and how it can be improved. |

Walt

Disney |

|

|